THE ACS TECHNOLOGY – ONE STEP AHEAD

Using innovative materials developed by us for the core boxes, we use the electrical conductivity of inorganic binders for conductive and thus geometry-independent homogeneous heating in the core box. Sand core drying from the inside out without forming shells. The recording of the electrical parameters in real time allows for the first time an real monitoring of the drying process and thus fulfils the requirements for a digitalisation of the process.

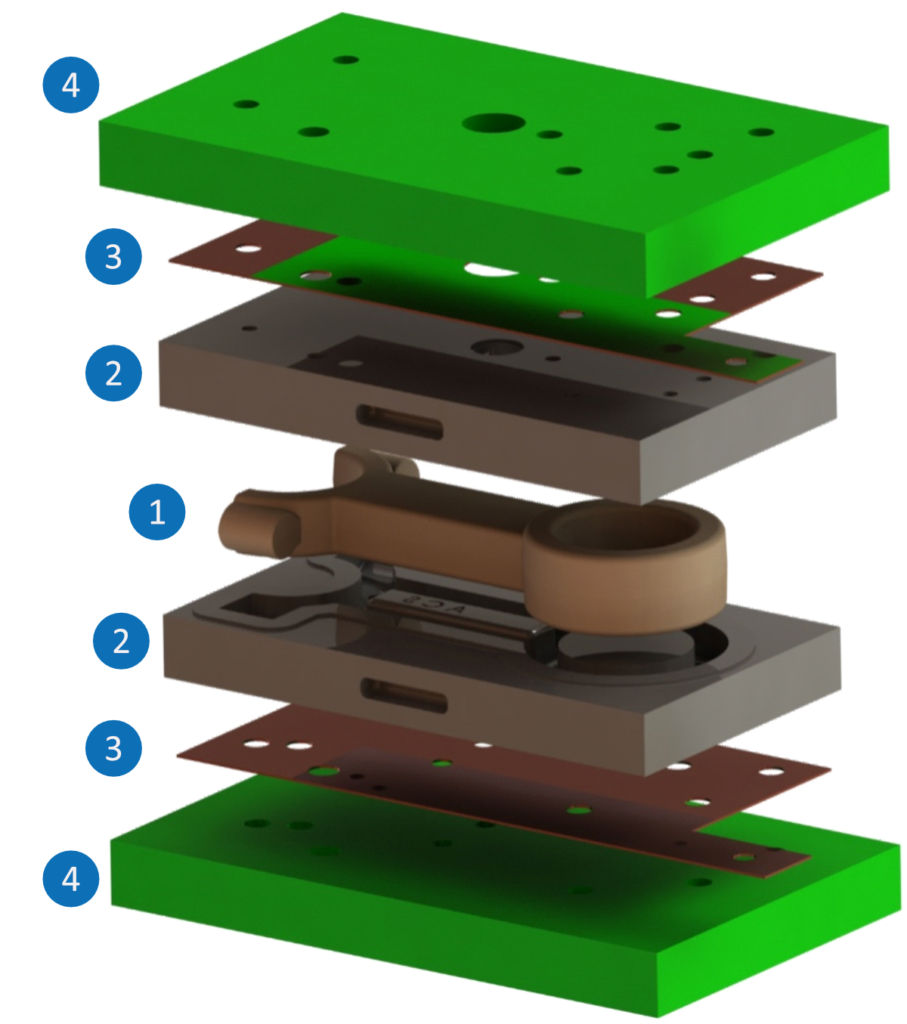

Layout of the ACS module

Our development can be installed on all existing core shooters. Thereby the core box module is essentially replaced.

The focus still is on the highest quality of the sand core drying process and the inorganic sand cores to be produced (1). To make this possible, we use special materials for the core boxes (2), whose electrical conductivity we adapt to the conductivity of your inorganic binder. If a voltage is now applied to the system in the form of electrodes (3), a homogeneous flow of current through the core box and the shot sand binder mixture results, as a result of which the sand core is conductively heated and drying begins. Highest safety standards isolate the module from the rest of the system (4) and ensure a safe production.

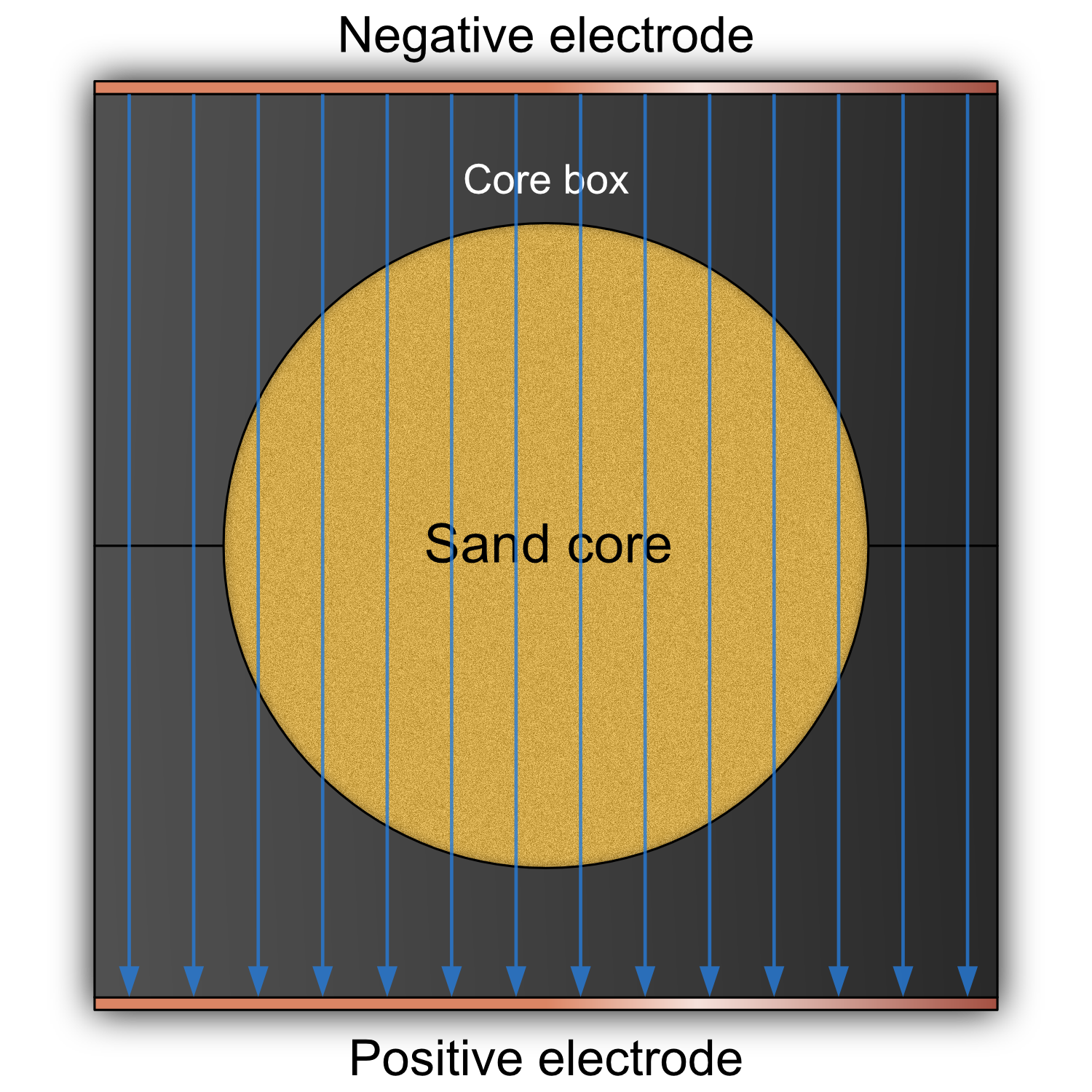

No adjustment of electrical conductivity

If the electrical conductivity of the core box does not match the electrical conductivity of the inorganic binder, this either leads to a heating of only the core box (i.e. it remains a hot-box process) or the required power does not reach the inorganic sand core.

With adjustment of electrical conductivity

Our specially developed ACS core box materials allow a homogeneous current flow through core box and inorganic sand core. Thus, the required energy can be supplied directly into the inorganic sand core. The result is a geometry-independent homogeneous heating of the inorganic sand core and a more efficient sand core drying process, which is not limited by the low thermal conductivity of the sand.

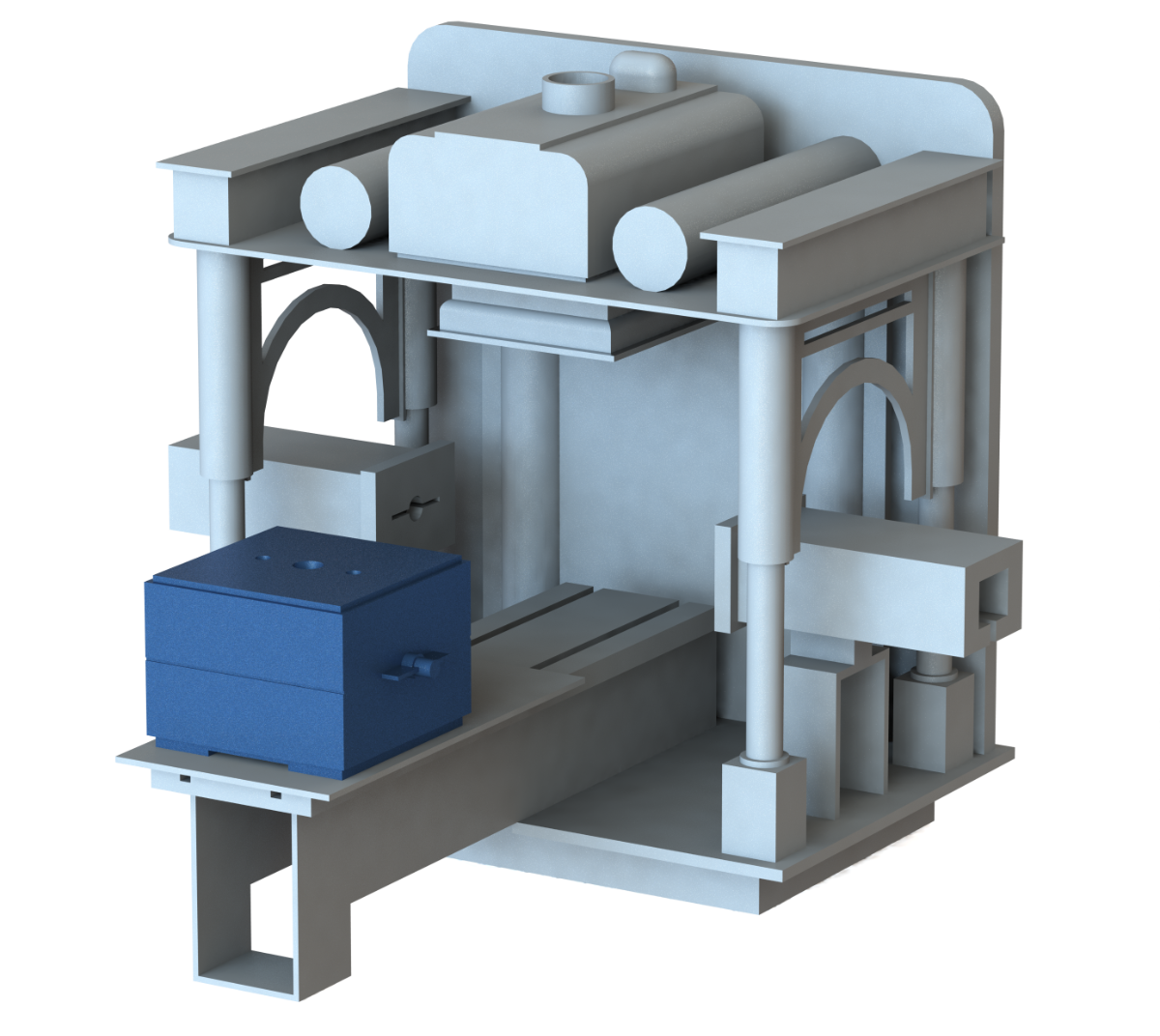

Upgrade of existing core shooters

Our technology can be used on all existing core shooter systems. We replace the existing core box technology with our core box modules, which are manufactured from materials developed by us. Depending on the quantities to be produced, we have various materials available from which we select the right one for you in consultation with you. Together with the required control technology, you will receive a total solution that increases your efficiency while reducing the costs and energy consumption of your inorganic sand core production. And all this at a significantly lower price than a new complete core shooting machine.

Related technologies and processes

Organic binder systems

Binders consisting of carbon compounds for moulding materials in foundry technology.

Further information: Link

Inorganic binder systems

Binders for foundry moulding materials usually based on water glass compounds.

Further information: Link

Cold-Box-Process (Organic)

Process for core production, in which the hardening of the cores is caused by a chemical reaction with amine gas.

Further information: Link

No-Bake Process (Organic)

Organic binder systems that cure independently at room temperature by polymerisation or polyaddition.

Further information: Link

Hot-Box-Process (Inorganic)

Process in which the cores are hardened by heat which is transferred from heated core boxes to the core.

Further information: Link