OUR ARTICLES AND PUBLICATIONS AT A GLANCE

You want to know more about our process? Contact us directly or use our previous publications.

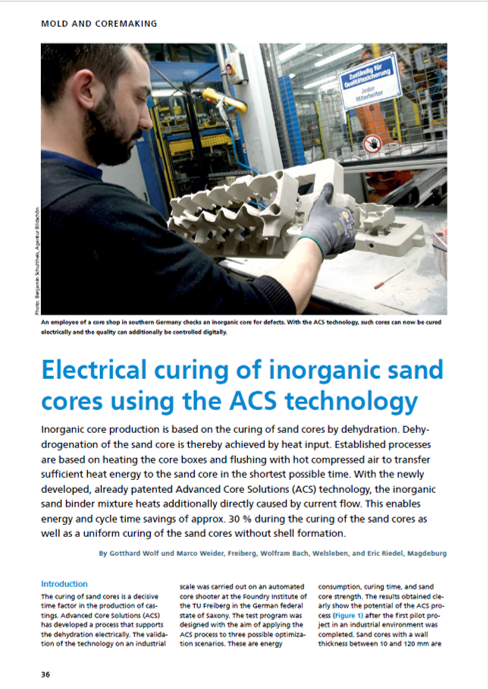

Electrical curing of inorganic sand cores (ACS process) CASTING PLANT & Technology 12/2020

Successful Validation of ACS-Technology with industrial core shooter demonstrating 30% reduction

In a direct comparison with conventional processes, the new ACS process shows significant overall cost savings. The savings are mainly due to two reasons. On the one hand, the direct use of electrical current, which does not have to be converted into heat with losses before the process, enables energy savings of up to 30 % compared to conventional processes. On the other hand, cycle time savings of up to 30 % are expected, which means that despite the possibly higher tool costs (depending on the material used) the annual operating costs can be massively reduced.

Click here for the full article… Link

Evolution of Hot-Box-Process – Overview & Simulation GIESSEREI SPECIAL 11/2020

Simulation of ACS-Technology to validate benefits of Hot-Box Evolution for inorganic sand cores

Complex casting parts with functional integration are based on the use of lost, mostly quartz sand-bound

cores. Due to their better ecological balance, tincreasingly inorganic binders are used today which are thermally cured. However, the potential of inorganic core production has not yet been fully exploited, since heat management

is challenging and the dehydration of sand cores often remains incomplete.

A new process development (ACS process) now effectively supports the hardening process by making the electrical use conductivity of the binder. The ACS process can now by fully simulated with FLOW-3D. This improves further the development steps by fully simulating the hardening process. The simulation is based on established FLOW-3D models for core shooters allowing to design, check and optimize the ACS-Technology in advance.

Click here for the full article… Link (German)

3. MOULDING MATERIAL FORUM MUNICH 2020 CONFERENCE 02/2020

Potential of new process for electrically resistance-based hardening of inorganic sand cores with new ACS-Technology

Increasingly stricter environmental requirements have led to the development and progressive establishment of inorganic binder systems which, compared to organic binder systems, harden thermally and thus require higher cycle times due to classic processes. This is where the ACS process comes in and aims to further develop the manufacturing process of inorganically bound cores, which can be implemented on all existing core shooters.

The process uses the electrical conductivity on which all inorganic binders are based to harden the cores. ….

Click here for the article… Link (German)

FOUNDRY GATE CHINA FOUNDRY ASSOCIATION 07/2019

New patented process to speed up the hardening of inorganic sand cores.

The ACS Project is focussing especially on the heat generation directly inside the sand cores by application of electrical currents. The benefits are not onlz faster sand core hardening but also better energy efficiency and reduced maintenance effort as external heat generation outside the core box could be eleminated.

Click here for the issue … Link

CASTING PLANT AND TECHNOLOGY INTERNATIONAL 03/2019

Sand core hardening: Digital quality with new ACS-Technology

The sand core quality is of decisive importance for the casting quality. The ACS solution generates the heat directly in the cores and thus hardens them completely.

Click here for the issue … Link

GLOBAL CASTING MAGAZINE CHINA FOUNDRY ASSOCIATION 03/2019

Development of newly patented process to speed up the hardening of inorganic sand cores

Sand cores are the backbone of modern foundry products and enable the most complex shapes. A newly patented process will improve the inorganic sand core hardening process by up to 33%.

Click here for the issue … Link

GIESSEREI SPECIAL – FORSCHUNG UND INNOVATION 01/2019

Electrical hardening of inorganic sand cores using Advanced Core Solutions (ACS) technology (GER)

Inorganic binder processes are based on the hardening of sand cores by means of dehydration. Dehydrogenation of the sand core is made possible by heat input. Established processes are based on heating the core boxes and rinsing with hot compressed air in order to transfer sufficient heat energy to the sand core in the shortest possible time. With the newly developed, already patented ACS technology, the inorganic sand binder mixture is additionally heated directly by means of a current flow. This enables …

CASTING PLANT AND TECHNOLOGY INTERNATIONAL 01/2019

Development of a new process for fast electrical hardening of inorgani sand cores

The development of a new process for hardening inorganic sand cores aims at a faster and more cost-effective core production.

Click here for the issue … Link

FOUNDRY-PLANET.COM THE B2B PORTAL Januar 2019

Development of a newly patented process to speed up the hardening of inorganic sand cores

Sand cores are the backbone of modern casting production and enable the realization of the most complex geometries. A newly patented process reduces the cycle time for hardening inorganic sand cores by up to 33%.

Click here for the issue … Link

MITTELDEUTSCHE MITTEILUNGEN Focus Foundry/Casting 01/2019

Faster and more efficient production of lost cores for high volume production (GER)

Heavy-duty and complex castings for modern automotive engineering are unthinkable without the use of equally high-quality sand cores. The production of lost cores and moulds is therefore one of the cornerstones for high-quality castings. Even though additive manufacturing is gaining ground in the field of core production, the majority of all cores are (and will continue to be in the foreseeable future) produced with core shooters that have so far used the cold box or hot box process. While the Cold Box process uses the shot cores, …

GIESSEREI Die Zeitschrift für Technik, Innovation und Management 01/2019

Development of a new process for electrical hardening of inorganic sand cores and moulds (GER)

Inorganics are becoming increasingly important for sand core production. The development of a new process for the hardening of inorganic sand cores by means of electricity aims at a faster and more cost-effective production of inorganic sand cores. The other advantages such as low energy consumption with homogeneous curing are promising.